Rohde & schwarz installs nokia private 5g network to run rule over industry 4. 0 creds

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

Rohde & Schwarz has installed a private 5G network from Nokia at its plant in Teisnach, Germany. The network test company wants to run the rule over cellular-enabled Industry 4.0

applications in a dedicated 5G setup. Nokia is involved in the testing, too; the pair are looking to gain insights to optimise 5G for smart factories. The network is running in the 3.7-3.8

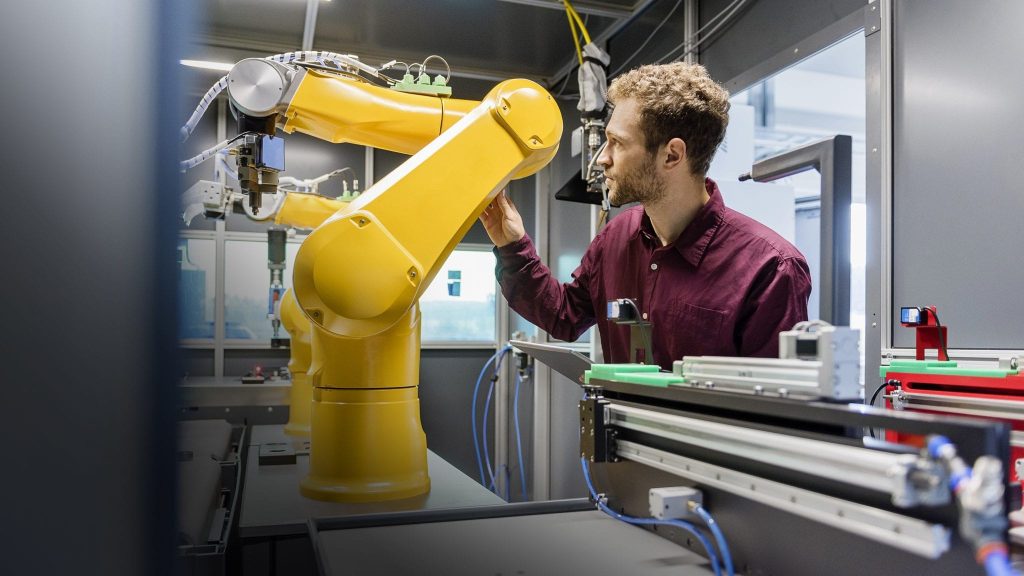

GHz band in Germany, with a vertical enterprise licence from the local regulator, BNetzA. Rohde & Schwarz will also look to bring intelligence and automation to its own production

processes, with a view to launch automated guided vehicles (AGV) and advanced robotics, and to validate its own network testing solutions, with a live view of 5G coverage, capacity and

configuration parameters in a real factory environment. The indoor deployment, which started in July, uses Nokia’s plug-and-play Digital Automation Cloud (DAC) solution. It covers an area of

about 1,500 square metres, and comprises 5G gNodeBs in non-standalone (NSA) mode using the n78 frequency band at 3.4 GHz, supplemented by LTE as the anchor in frequency band 40 at 2.3 GHz.

Rohde & Schwarz and Nokia are using test solutions from the former to assess site acceptance and coverage, including its FPH handheld spectrum analyzer, the TSMx6 scanning receiver,

Android smartphone-based network optimizer, and the 5G STS site testing solution. Rohde & Schwarz commented: “5G introduces the possibility of faster and safer operations, as well as new

capabilities and efficiencies in industrial processes. It also creates some degree of complexity and performance demands for the network. Industry 4.0 applications in particular create

specific demands on communications technology with regard to latency, reliability and security.” It said smart-factory deployments of industrial 5G should go through certain test phases,

first. These include rollout preparation and spectrum clearance for a clean RF environment inside the factory, acceptance testing for correctly installed network infrastructure, coverage and

performance testing, real-time service quality monitoring, and regulatory checks.