An individual alginate lyase is effective in the disruption of laminaria digitata recalcitrant cell wall

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT In the present study, 199 pre-selected Carbohydrate-Active enZymes (CAZymes) and sulfatases were assessed, either alone or in combination, to evaluate their capacity to disrupt

_Laminaria digitata_ cell wall, with the consequent release of interesting nutritional compounds. A previously characterized individual alginate lyase, belonging to the family 7 of

polysaccharide lyases (PL7) and produced by _Saccharophagus degradans_, was shown to be the most efficient in the in vitro degradation of _L. digitata_ cell wall. The alginate lyase

treatment, compared to the control, released up to 7.11 g/L of reducing sugars (_p_ < 0.001) and 8.59 mmol/100 g dried alga of monosaccharides (_p_ < 0.001), and reduced cell wall

fluorescence intensity by 39.1% after staining with Calcofluor White (_p_ = 0.001). The hydrolysis of gel-forming polymer alginate by the alginate lyase treatment could prevent the trapping

of fatty acids and release beneficial monounsaturated fatty acids, particularly 18:1_c_9 (_p_ < 0.001), to the extracellular medium. However, no liberation of proteins (_p_ > 0.170) or

pigments (_p_ > 0.070) was observed. Overall, these results show the ability of an individual alginate lyase, from PL7 family, to partially degrade _L. digitata_ cell wall under

physiological conditions. Therefore, this CAZyme can potentially improve the bioavailability of _L. digitata_ bioactive compounds for monogastric diets, with further application in feed

industry. SIMILAR CONTENT BEING VIEWED BY OTHERS CHARACTERIZATION OF ALGINATE EXTRACTED FROM _SARGASSUM LATIFOLIUM_ AND ITS USE IN _CHLORELLA VULGARIS_ GROWTH PROMOTION AND RIBOFLAVIN DRUG

DELIVERY Article Open access 18 August 2021 PRESERVATION OF FRESHLY-CUT LEMON SLICES USING ALGINATE-BASED COATING FUNCTIONALIZED WITH ANTIOXIDANT ENZYMATICALLY HYDROLYZED RICE

STRAW-HEMICELLULOSE Article Open access 08 November 2024 SIMULTANEOUS PRODUCTION OF FATTY ACIDS AND AMINO POLYSACCHARIDES FROM NORWAY SPRUCE HYDROLYSATES USING OLEAGINOUS _MUCOR

CIRCINELLOIDES_ Article Open access 23 April 2025 INTRODUCTION Due to an increasing interest in the use of macroalgae for food and feedstuffs1, as well as for pharmaceutical industries,

organic fertilizers, eutrophication inhibition, bioremediation and biogas generation1, their cultivation has been steadily growing over the last decade. The nutritional profile of

macroalgae, although variable among species and depending on growth location and harvesting season1, consists of numerous vitamins, minerals, pigments, phenolic compounds, carbohydrates and

high quality proteins1. Carbohydrates comprise a high proportion of macroalgae biomass (from 4 to 76% dry matter, DM)2, whereas lipids are usually found in small amounts (< 5% DM) with

values up to 1.13% DM in brown algae3. However, their lipid profile can be rich in monounsaturated (MUFA) and polyunsaturated (PUFA) fatty acids4,5,6, which might have beneficial effects on

human health7. _Laminaria_ sp_._ are seawater multicellular eukaryotic and autotrophic brown macroalgae, which are amongst the most cultivated seaweeds worldwide, representing the largest

biomass in coastal regions8. Brown macroalgae have a distinct carbohydrate-rich cell-wall9,10, which comprises up to 45% DM of alginate and fucose-containing sulphated polysaccharides

(FCSPs) (fucans or homofucans and fucoidans or heterofucans), as well as small amounts of cellulose (1 to 8% DM)11, β-1,3 glucans, unbranched mixed-linkage β-D-glucans

(1,3-and-1,4-β-D-glucose residues) masked by alginate12 and arabinogalactans linked to proteins13. The proportion of alginates, fucoidans and cellulose was found to be 3:1:110. Alginate is a

linear polysaccharide composed of only two epimers, β-1,4-D-mannuronic (M) and α-1,4-L-guluronic (G) acids, arranged in heteropolymeric (MG) or homopolymeric (MM or GG) blocks along the

polymer chain11. FCSPs are composed of two different backbones with α-1,3- or alternating α-1,3-/α-1,4-linked L-fucose residues. These motifs form acetylated or branched structures

presenting one to three sulphate esters on positions _O_-2, _O_-3 or _O_-411. Laminarin is a polysaccharide located in intracellular vacuoles that constitutes the carbon storage of

macroalgae and is composed of (1,3)-β-D-glucopyranose residues with some 6-O-branching in the main chain and β-1,6-intrachain links14,15. These polysaccharides were found to have bioactive

properties with relevance for potential applications in functional foods and feeds, cosmetics and pharmaceutical products13,14,15. For instance, alginate was shown to reduce blood pressure

and cholesterol and to have antimicrobial and anticancer activities15; FCSPs were described as antioxidant, anti-inflammatory, immune-stimulant, antimicrobial and anticancer compounds13,15;

and laminarin was reported as an anticancer, anti-inflammatory, immunostimulatory, anticoagulant and antioxidant14,15 agent. However, cell wall carbohydrates are organized in a complex

cross-linked matrix, resulting in a highly recalcitrant cell wall that resists breakage and serves as a natural defence mechanism for algae9. In fact, alginate cross-links with phenolic

compounds and constitutes gel-forming and hydroscopic polymers that control cell wall rigidity11. These polymers form a network that embed fucose-containing sulphated polysaccharides. The

latter are tightly assembled to cellulose microfibrils by cross-linkage11. The intricate macroalga cell walls have been described to exert anti-nutritional effects for monogastric animals,

by trapping valuable nutrients, with a concomitant decrease in the efficiency of feed digestion and absorption16. The presence of complex polysaccharides in seaweed cell walls can also

decrease the rate of algae biomass hydrolysis during the production of renewable energies, thus reducing bioethanol and biogas yields17. Mechanical processes, such as hammer mill, are

usually applied for incorporation of seaweed in diets for monogastric animals1. However, mechanical methods are less specific for macroalgae cell disruption than enzymatic procedures.

Therefore, the latter can be more advantageous for the release of algae valuable nutritional and bioactive compounds and increase of their bioavailability18. The effectiveness of exogenous

enzymes (_i.e._ cellulases, xylanases19,20,21,22 and a mixture of carbohydrases18) on hydrolysing algae biomass with an increase of protein extraction or digestibility was previously

demonstrated for green (i.e. _Ulva rigida_)18 and red (e.g. _Palmaria palmata_, _Gracilaria_ sp. and _Chondrus_ sp.)19,20,21,22 seaweeds. Other studies reported the use of cellulases,

alginate lyases23,24,25 and a carbohydrase mixture26 for the degradation of brown macroalgae biomass (_Laminaria digitata_23,25, _Saccharina latissima_24,25 and a mixture of different

species including _Sargassum_ sp.26) envisaging biotechnological applications. These applications consisted in the production of bioethanol and biogas23,25, algae saccharification24 and

extraction of bioactive compounds26. Therefore, exogenous Carbohydrate-Active enzymes (CAZymes) could be a suitable option to deconstruct macroalgae cell wall, similarly to what was recently

described by our research team for microalgae27,28. Moreover, these exogenous enzymes were shown to improve the nutritional value of cereal-based diets29,30, with the consequent industrial

application as feed additives for poultry and pigs31. Additionally, the use of sulfatases could be of major importance for the degradation of the recalcitrant structure of branched and

sulphated FCSPs, as reported in a recent study32. Thus, we hypothesised that CAZymes and sulfatases could, individually or in combination, degrade the recalcitrant _L. digitata_ cell wall,

with the consequent improvement of nutrients bioavailability. Cell wall disruption was assessed by fluorescence microscopy, reducing sugars and oligosaccharides profile after incubation of

macroalga with the enzymes. The release of nutritive and bioactive compounds from macroalga, following the enzyme treatment, was assessed by quantifying proteins, pigments and fatty acids.

RESULTS CAZYMES AND SULFATASES SELECTION AND EVALUATION OF EXPRESSION AND PURITY OF RECOMBINANT ENZYMES All of the CAZYmes and sulfatases selected for the initial screen were chosen for

their activity, either determined or predicted, towards specific compounds of brown macroalgae cell walls, like alginate, FCSFs and cellulose11. Furthermore, most are produced by marine

halophilic bacteria, which are organisms likely adapted to feed on algae biomass. The catalytic activity and the biochemical properties of the majority of the candidates were previously

described in the literature and their amino acid sequences can be accessed in Genbank (see Supplementary Table S1). Seventeen of the selected CAZYmes (ID 166 to 174, 184, 189 to 195) did not

have their activity and substrate specificity previously characterized, but were selected due to sharing high homology (see Supplementary Table S1 for Genbank accession numbers) to some of

the other well-characterized candidates. In order to evaluate the soluble protein yield for each enzyme, a qualitative scale was used based on the protein concentration (g/L): -, 0.0; + ,

0.1 > 2.1; + + , 2.1 > 4.1; + + + , 4.1 > 6.1; + + + + , > 6.1 (see Supplementary Table e S1). From the 199 recombinant enzymes, 23 did not express (-), 81 had low

expression levels or were mostly insoluble ( +) and 95 had good expression and solubility levels (+ + , + + + , + + + +). Among low expressing enzymes, 4 were slightly degraded (ID 5,

69, 73 and 129). Among high expressing enzymes, 1 had low solubility, 1 was degraded and 3 (ID 147, 151 and 184) had a different SDS-PAGE migration pattern than what was expected from the

calculated molecular weight (data not shown). All soluble protein fractions were enriched by a high throughput IMAC protocol before the activity screens (see Supplementary Fig. S1).

SCREENING OF INDIVIDUAL ENZYMES FOR _LAMINARIA DIGITATA_ CELL WALL DISRUPTION Each one of the 176 CAZymes and sulfatases with low to high expression levels (see Supplementary Table S1) was

individually incubated with a macroalga suspension in phosphate buffered saline (PBS) solution for an evaluation of their ability to degrade _L. digitata_ cell wall. The majority of enzymes

was unable to deconstruct alga biomass (see Supplementary Table S2), but 8 individual enzymes (ID 6, 18, 20, 21, 22, 28, 29 and 46) had a measurable capacity to degrade the cell wall of _L.

digitata_, as shown in Table 1. This ability was assessed by both the release of reducing sugars, as evaluated through the 3,5-dinitrosalicylic acid (DNSA) method, and the decrease of

fluorescence intensity from Calcofluor white stained cell walls. The fact that brown macroalgae cell walls form an intricate carbohydrate structure11 will allow the evaluation of cell wall

integrity loss by assessing the reduction of Calcofluor white staining fluorescence intensity, even though the dye only binds specifically to minor compounds of the cell wall (cellulose and,

to some extent, mixed-liked 1,3–1,4-β-glucans)12,33. Therefore, the data in Table 1 is presented according to two qualitative scales: the first scale is based on the amount of released

reducing sugars (g/L): -, 0.00 < 2.77; + , 2.77 < 3.99; + + , 3.99 < 5.20; + + + , 5.20 < 6.42; and + + + + , > 6.42; whereas the second one is based on the decrease of

fluorescence intensity (%): -, 0.00 < 9.92; + , 9.92 < 20.0; + + , 20.0 < 29.9; and + + + , 29.9 < 38.5; + + + + , > 38.5. For the enzymes with ID 6 and 46, the release

of reducing sugars (average of 0.46 g/L) was in the lower level considered in Table 1 and they caused only a low to intermediate decrease of fluorescence intensity (up to 22.3%). However,

enzyme with ID 46 was selected because its predicted substrate is α-linked L-fucopyranosyl units, which are the main residues found in one of the major components of brown seaweed cell

walls, the FCSPs11. Although the substrate for the enzyme with ID 6 (mixed linked 1,3–1,4-β-glucans) is only a minor component of brown macroalgae cell walls, its insoluble nature can impact

the degradation of algae cell wall, mainly through the association with a major cell wall polysaccharide, the alginate12. SELECTION OF THE MOST ACTIVE ENZYMES AND ASSESSMENT OF THEIR

SYNERGISTIC ACTION In order to disclose synergistic actions among individual enzymes, an eight-enzyme mixture based on the initial screening (Table 1), was compared to a three-enzyme mixture

(ID 18, 22 and 46) (Table 2, Figs. 1, 2 and 3). These three enzymes were selected based on their organism of origin, thermostability and main substrate. Indeed, laminarinase (ID 18) and

alginate lyase (ID 22) were isolated from marine and halophilic bacteria (_Thermotoga napolitana_34 and _Saccharophagus degradans_35, respectively), and were described as being

thermoresistant with optimum catalytic activities at 85 to 95 ºC34 and 50 ºC35, respectively. Although the enzyme with ID 46 was from a non-marine and non-halophilic bacterium

(_Lactobacillus casei_)36, it was relatively thermostable, with an optimum temperature of 42 ºC36, and acted towards a main constituent of brown algae cell wall (α-linked L-fucopyranosyl

units)11. The eight-enzyme mixture led to a release of reducing sugars of 6.74 g/L, which corresponded to an increase of only 0.57 g/L compared to the three-enzyme mixture. Then, the latter

mixture was compared to the activities of each enzyme composing it. It was observed that, when enzyme ID 22 enzyme was individually incubated with _L. digitata_ suspension, the value of

released reducing sugars was identical (p = 0.443) to the three-enzyme mixture (6.17 g/L). In contrast, the released reducing sugars by the other individual enzymes (4.57 g/L for enzyme ID

18, and 0.50 g/L for enzyme ID 46) were significantly lower than that of mixture (p < 0.001). Altogether, these results indicate the absence of significant (p > 0.050) additive or

synergistic effects among enzymes. The ratios of released reducing sugars were found to be: alginate lyase _versus_ three-enzyme mixture = 101.3%; alginate lyase _versus_ laminarinase =

136.6%, and alginate lyase _versus_ fucosidase = 1242%. Regarding the above values, the alginate lyase ID 22 was selected as the most active enzyme for the degradation of _L. digitata_ cell

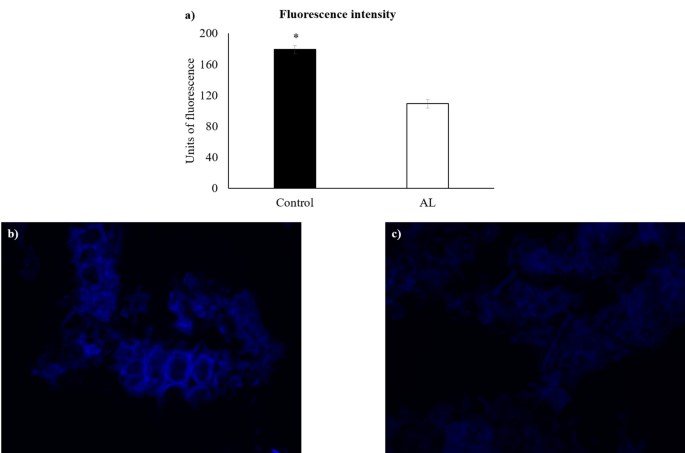

wall. EFFECT OF ALGINATE LYASE ON _LAMINARIA DIGITATA_ CELL WALL INTEGRITY The extension of released reducing sugars and decreased fluorescence pixels of stained cell walls promoted by the

selected alginate lyase (ID 22; Provisional Patent number, INPI, Portugal) are presented in Table 1. The latter is also illustrated in Figs. 1a, b and c. The amount of reducing sugars (7.11

g/L) was significantly increased (p < 0.001), whereas the number of pixels (179 to 109; 39.1% decrease of fluorescence intensity) was significantly reduced (p = 0.001) with the enzyme ID

22, when compared to the control assay. ACTIVITY, THERMOSTABILITY AND PROTEOLYSIS ASSAYS OF ALGINATE LYASE Catalytic activity of alginate lyase (ID 22) was evaluated by both UV spectroscopy,

using alginate as substrate at pH 7.5 and 37 °C, and DNSA method. The enzyme showed an activity of 1.52 ± 0.026 AU/min @233 nm and 0.282 ± 0.0025 g reducing sugars/L × min. The purified

(> 90% purity) alginate lyase was tested for its thermostability and proteolysis resistance. For the thermostability assay, the intact protein was subjected to a range of temperatures (30

to 80 ºC) (Fig. 4). The enzyme maintained its stability at 37 and 40 ºC. Although significant (p < 0.001), only a small variation of protein concentration was found between these two

temperatures (0.81 to 0.74 g/L, respectively). However, the stability of alginate lyase declined abruptly between 40 °C and 50 ºC, with the enzyme being completely degraded at 50 ºC. The

proteolytic resistance of alginate lyase is shown in Table 3 and Fig. 5. The enzyme showed partial resistance over the entire assay time. EFFECT OF ALGINATE LYASE ON THE RELEASE OF MONO- AND

OLIGOSACCHARIDES FROM _LAMINARIA DIGITATA_ CELL WALL Figure 6 shows the influence of alginate lyase treatment on the release of mono- and oligosaccharides from _L. digitata_ cell wall. The

composition of mono and oligosaccharides was a mixture of compounds, not individually identified due to its complexity and lack of some commercial standards. With the enzyme treatment,

monosaccharide concentrations significantly increased (_p_ < 0.001), from 0.02 to 8.64 mmol/100 g dried alga, in relation to the control. Although the amount of oligosaccharides did not

significantly differed (_p_ = 0.260) between assays, a numerical increase, from 1.19 to 2.57 mmol/100 g dried alga, was found for the alginate treatment. In addition, residual amounts of

glucose (8.24 × 10–4 mmol/100 g dried alga) were released from _L. digitata_ biomass with the alginate lyase treatment (data not shown). EFFECT OF ALGINATE LYASE ON THE RELEASE OF PROTEINS

AND PIGMENTS FROM _LAMINARIA DIGITATA_ BIOMASS The influence of alginate lyase (ID 22) treatment on pigment and protein concentrations in the supernatant and residue fractions is presented

in Table 4. These results indicate if the hydrolysis of the viscous gel-like structure formed by the polymer alginate11 led to the release of trapped valuable nutrients. The incubation of

alga with the enzyme did not trigger (_p_ > 0.100) the release of protein from _L. digitata_ cells and, thus, a similar protein content was found for the enzyme and control assays (31.1

and 39.9 mg/g alga for the supernatant, and 114 and 91.7 for the residue). Additionally, no significant differences (_p_ > 0.071) between assays were observed for chlorophyll, carotenoid

and fucoxanthin contents in both centrifugation fractions. EFFECT OF ALGINATE LYASE ON THE RELEASE OF FATTY ACIDS FROM _LAMINARIA DIGITATA_ BIOMASS Fatty acid profile in residue and

supernatant fractions, after incubation with the alginate lyase (ID 22), was analysed to determine if the enzyme treatment led to the release of fatty acids from _L. digitata_ cells to the

external environment (Table 4), since these nutrients could have been trapped by the gel-forming structure of alginate. For both supernatant and residue fractions, the percentage of fatty

acids were as follows: saturated fatty acids (SFA) > MUFA > PUFA > _n_-6 PUFA > _n_-3 PUFA. In the supernatant, the amount of total fatty acids was increased (_p_ = 0.001) from

1.30 to 4.22 mg/g dried alga with the alginate lyase treatment. In fact, higher percentages of total MUFA (_p_ < 0.001) were found in the presence of enzyme, with a major contribution of

18:1_c_9 (_p_ < 0.001) and additional contributions of 16:1_c_9, 18:1_c_11 and 20:1_c_11. In addition, the percentage of total SFA was significantly decreased (_p_ = 0.001) with the

alginate lyase treatment, particularly of 12:0, 14:0, 16:0, 18:0, 20:0 and 22:0, as well as the amount of total _n_-6 PUFA (_p_ = 0.038). The 18:2_n_-6 fatty acid tended to decrease (_p_ =

0.053) with the alginate lyase treatment, although it was found in small percentages for both assays (2.08% for control and 1.35% for the enzyme). In the residue fraction, the alginate lyase

treatment caused no significant differences (_p_ > 0.096) either in the amount of total fatty acids or in the percentage of individual fatty acids, leading only to a significant decrease

of total SFA (_p_ = 0.037) comparatively to the control. DISCUSSION A large library of 176 CAZymes and 23 sulfatases was produced to test the hypothesis that some of these enzymes, with

well-characterized biochemical characteristics (see Supplementary Table S1), could disrupt the recalcitrant cell wall of _L. digitata_ with the consequent increase of nutrients availability.

The production of enzymes was done in a high-throughput (HTP) platform and consisted of several steps, including gene synthesis, gene cloning, recombinant protein expression in _E. coli_

cells and protein purification. These 199 enzymes were selected based on the polysaccharide matrix composition of macroalga cell wall, which comprises mainly alginate and fucose-containing

sulphated polysaccharides, as well as minor amounts of cellulose, putative hemicellulose11 and mixed-linked β-glucans12. Laminarin13,14,15 is the main carbon storage of brown seaweeds. In

addition, the enzyme origin was also attended in the selection, being 121 of them from marine and halophilic bacteria and 41 from thermophilic or hyperthermophilic bacteria. An individual

screening of the enzymes was performed in order to assess their ability to degrade _L. digitata_ cell wall, which was evaluated by measuring the release of reducing sugars and the intensity

of microscopic fluorescence. Afterwards, the 8 selected recombinant enzymes (see Table 1) were combined and tested in order to obtain a maximum disruption of _L. digitata_ cell wall, and

then reduced to a combination of 3 enzymes (laminarinase ID 18, alginate lyase ID 22 and α-L-fucosidase ID 46). However, the alginate lyase led to a degradation of macroalga cell wall

similar to the simultaneous use of the 3 enzymes. The absence of synergistic and additive effects between enzymes indicates that, as previously reported for brown macroalgae11, the different

polysaccharides of _L. digitata_ cell wall, namely alginate and FCSFs, are not interlinked within the cell wall structure. This enzyme (ID 22) belongs to the family of polysaccharide lyase

7 (PL7) and is produced by _S. degradans_35. It possesses poly-β-mannuronate (EC 4.2.2.3) and, to a lesser extent, poly-β-guluronate (EC4.2.2.11) lyase activities. The alginate lyase

endolytically depolymerize alginate by β-elimination, having both alginate and oligo-alginates as its main substrates35. This enzyme (ID 22) showed to be resistant to proteolysis and

thermostable until 40 ºC, with an abrupt decrease of thermostability between 40 and 50 ºC. These results are likely due to the tertiary structure of protein that confers both thermotolerance

and an inherent proteinase resistance37. The instability of this enzyme at high temperatures (> 50 ºC) over an increasing period of time was already reported35, even though maximum

catalytic activity was described as 50 ºC35. This aspect might be explained by the fact that _S. degradans_ is a mesophilic, instead of a thermophilic, Gram-negative bacterium. However, this

organism is one of the strongest marine biomass degraders, being capable of hydrolysing a great variety of polysaccharides38. Furthermore, the efficiency of the recombinant

mannuronate-specific alginate lyase from PL7 family (ID 22) on releasing reducing sugars (7.11 g/L) from brown macroalga cell wall was firstly demonstrated herein. In fact, only one previous

study25 reported the recovery of reducing sugars from _L. digitata_ and _S. latissima_ biomass (10 and 11 g/L, respectively), through the action of a commercial mannuronate-specific

alginate lyase, belonging to the PL5 family (Genbank accession numbers: SUJ15243.1 and SUJ21107.1). This enzyme was produced by _Sphingobacterium multivorum_ during the enzymatic

pre-treatment of algae biomass for biogas production. However, in the present study, a well-characterized endotype PL5 alginate lyase (ID 41) produced by _Sphingomonas_ sp. A1 (Genbank

accession number BAB03312.1), which specifically acts on poly-β-mannuronate regions (EC 4.2.2.3) and depolymerizes alginate into tri- and disaccharides39, was significantly (_p_ < 0.050)

less efficient at releasing reducing sugars (1.70 g/L) than the 3 analysed enzymes from PL7 family (average of 6.07 g/L). The release of reducing sugars with alginate lyase (ID 22) is

possibly related to an increase of monosaccharides and, although not significant, of oligosaccharides released from _L. digitata_ biomass40. Although a recombinant alginate lyase with the

same catalytic site as the enzyme with ID 22 was previously shown to produce unsaturated oligoalginates (degrees of polymerization of 2 to 5) but not monosaccharides35,40, a mixture of

unidentified monosaccharides, which was probably composed of uronic acid residues but needs further analysis, was released by the enzyme treatment (ID 22) in the present study. The fact that

residual amounts of glucose (8.24 × 10–4 mmol/100 g dried macroalga) were obtained with the alginate lyase treatment might indicate that the breaking down of viscous-gel like matrix of

alginate lyase (ID 22) released trapped laminarin from the intracellular algae compartment, which became available for a possible autohydrolysis, as previously reported23. Although, to date,

a selective effect of alginate lyase towards carbohydrates from brown seaweed cell wall was never reported, two studies evaluated the release of glucose from brown macroalgae biomass during

either bioethanol production23 or algae saccharification24. The first described a slight release of glucose from _L. digitata_ biomass, by using a commercial mannuronate-specific alginate

lyase, from an unknown family, produced by _Sphingobacterium spiritivorum_. The latter, similarly to the present study, reported no effect of 3 recombinant alginate lyases from PL7 family on

the release of glucose from _S. latissima_. In the present study, the decrease of cell wall fluorescence intensity (39.1%) promoted by alginate lyase (ID 22) indicates a partial alga cell

wall degradation, similarly to what was observed by our research team for microalgae27,28. Considering that Calcofluor white preferentially binds to cellulose and, to some extent,

mixed-liked 1,3–1,4-β-glucans in macroalgae cell walls rather than to acidic polysaccharides12,33, like alginate and FCSPs in brown algae11, the degradation of alginate seems to have

compromised the whole integrity of the intricate macroalgae cell wall structure with a decreased dye binding by cellulose and mixed-liked glucans. The cell wall disruption was likely due to

the ability of enzyme with ID 22 to degrade polymannuronate residues of alginate and consequently compromise cell wall rigidity that is controlled by the gel-forming structure alginate11. In

fact alginate from _L.digitata_ cell wall was found to be mainly composed of mannuronic acid (M) instead of guluronic acid (G) residues (M/G ratio between 1.99 and 3.0)41. The preferential

activity of alginate lyases from PL7 family on polymannuronic acid rather than on polyguluronic acid or alginate was demonstrated in a recent study42 when the enzyme produced by a marine

fungus _Paradendryphiella salina_ was incubated with 3 different brown alga species _(Ascophyllum nodosum_, _S. latissima_ and _Fucus serratus_). However, the activity of PL7 alginate lyase

(ID 22) is not specific for polymannuronate as this enzyme can also act on polyguluronate residues of alginate (Kim et al., 2012). Conversely, the catalytic residues of enzyme with ID 41

(Genbank accession number: Q9KWU1) were shown to strictly bind to mannuronic acid residues39. This latter aspect can help to explain why PL7 alginate lyase (ID 22) was more efficient on

degrading _L. digitata_ cell wall than the PL5 alginate lyase (ID 41), in the present study. Conversely to carbohydrates, alginate lyase (ID 22) did not release (hydro-) soluble proteins

from _L. digitata_ cells to the external environment. These results can be due to the extracellular presence of phenolic compounds (_i.e._ phlorotannins) previously cross-linked to

alginates11, which have protein-linkage properties43, and hydrocolloidal anionic polysaccharides (_e.g._ oligoalginates)44. These compounds would limit the access and quantification of

proteins, through the increased viscosity of extraction medium, a phenomenon that was indeed observed in the supernatants from alginate lyase treatment, and reported for other

carbohydrases37. Their presence was already found to be a limiting factor of protein extraction when cellulase and xylanase acted on _P. palmata_19,21,45. In addition, no release of pigments

from _L. digitata_ cells to the extracellular medium was found with the alginate lyase treatment. The amounts of pigments in control assay residues were slightly different from the values

(mg/g dried alga) previously reported for _Laminaria_ sp.46 (0.124 _versus_ 0.184 for chlorophyll _a_, 0.006 _versus_ 0.014 for chlorophyll _b_, 0.034 _versus_ 0.026 for total carotenoids),

which was probably due to the use of different solvents for pigment extraction46, as well as variations on alga species and harvesting season47. Similarly to what was reported for

microalgae27,28, the alginate lyase (ID 22) could not disrupt the long parallel lamellae of tree thylakoids in cytoplasmic plastids of brown seaweeds that contain the light harvesting

complex with photosynthetic pigments48. These results are explained by the absence of activity of the enzyme with ID 22 on the lipid and protein-rich plastid membrane, since this enzyme acts

specifically on alginate and oligoalginates35. Enzyme with ID 22 was able to release fatty acids from alga biomass to the extracellular medium (supernatant), although without a significant

effect on the algal incubation residue. To date, only one study49 suggested the change of fatty acid profile promoted by alginate lyases on brown seaweeds, although using a alginate lyase

from PL5 family acting on _Undaria pinnatifida_ and with no statistical analysis of data. Thus, the present study is the first that show the significant effect of a recombinant alginate

lyase (PL7) on fatty acid profile of a brown macroalga (_L. digitata_). It was observed an increase of total MUFA, such as 16:1_c_9, 18:1_c_9, 18:1_c_11 and 20:1_c_11 fatty acids, and a

concomitant decrease of total SFA, including the major 16:0 and 18:0 fatty acids, released to the supernatant. In fact, oleic acid (18:1_c_9) was increased by threefold with the alginate

lyase treatment. These results might be explained by the release of phlorotannins to the extraction medium by the action of alginate lyase, as previously reported11. In fact, tannins were

previously shown to inhibit the complete biohydrogenation of C18 fatty acids in animals50. The latter aspects need to be further exploited due to the benefits that increasing the release of

MUFA, such as 18:1_c_9, in detriment of SFA, have to human health, particularly on preventing cardiovascular diseases7. CONCLUSION The results obtained in the present study indicate that the

sole use of an alginate lyase from PL7 family, under physiological conditions, can lead to a partial degradation of _L. digitata_ cell wall. The disruption of macroalga cell wall would

allow the release of trapped bioactive compounds with important value for biotechnological and feed industries. The high nutritional value of these compounds may stimulate the use of

exogenous enzymes, as novel biocatalysts, to supplement diets containing _L. digitata_ for monogastric animals. Further work is currently in progress in our research laboratories to assess

the effectiveness of using this alginate lyase as a supplement for monogastric diets with high incorporation levels (10–15% of diet weight) of _L. digitata_. METHODS MACROALGA PRODUCTION The

low heat-dried brown macroalgae _L. digitata_ was obtained from Algolesko Company (Plobannalec-Lesconil, Brittany, France), where it was cultivated in seawater offshore ponds and

biologically certified by Ecocert. Before it was used for the in vitro incubations, the macroalgae was ground in a knife mill (Grindomix GM 200, Retsch Gmbh, Germany), sieved through a woven

wire mesh sieve with a diameter of 63 µm (Retsch Gmbh, Germany) and stored at -20 ºC. HIGH-THROUGHPUT GENE SYNTHESIS, CLONING AND PROTEIN EXPRESSION/PURIFICATION OF RECOMBINANT ENZYMES

One-hundred and seventy-six CAZymes with high potential for degradation of macroalgae cell wall were selected from a diverse repertoire, including glycoside hydrolases (GH), pectate lyases

(PL) and carbohydrate esterases (CE). In addition, 23 sulfatases were selected for screening, as they are also likely involved in the degradation of sulphated polysaccharides from macroalgae

cell walls51. The generation of 199 recombinant plasmids, as well as the expression and purification of the corresponding enzymes, followed the procedures described in previous

studies27,28. One-hundred and sixty-six coding genes for the selected enzymes were synthesised in vitro using NZYGene Synthesis kit (Nzytech, Portugal), whereas the other 33 coding genes

were synthesised by Twist Bioscience (San Francisco, CA, USA). The sequence of each enzyme is presented in Supplementary Table S1. After optimisation of synthetic genes for cloning and

subsequent expression in _Escherichia coli_, 166 genes were directly cloned into the bacterial expression vector pHTP1 (Nzytech, Portugal) using NZYEasy Cloning & Expression kit I

(Nzytech, Portugal), whereas 33 genes were cloned in pET-29b( +) (Twist Bioscience, San Francisco, CA, USA). The generated recombinant plasmids were subjected to inducible T7 promoter

control, while encoding the 199 enzymes fused to an N-terminal His6-tag that facilitates purification through Immobilised Metal Affinity Chromatography (IMAC). All recombinant plasmids were

sequenced to ensure that no mutations accumulated during gene synthesis and were used to transform _E. coli_ BL21 (DE3) cells in 24 deep-well plates, followed by protein production, cell

harvesting and protein purification. An IMAC high-throughput method based on an automated protocol that allows the purification of 96 proteins simultaneously was performed, as previously

reported52 but with some modifications. Briefly, 1 mL of crude cell lysates were incubated with 200 μL of 25% Ni2+ Sepharose 6 Fast flow resin (GE Healthcare, IL, USA) and transferred into

96-well filter plates (Macherey–Nagel, Duren, Germany)52. The wells were washed twice with 1 mL of 10 mM Imidazole buffer (10 mM Imidazole, 50 mM NaHepes, 1 M NaCl, 5 mM CaCl2, at pH = 7.5)

and once with 1 mL of 35 mM Imidazole buffer (35 mM Imidazole, 50 mM NaHepes, 1 M NaCl, 5 mM CaCl2, at pH = 7.5). Then, the proteins were eluted with 300 µL of 300 mM Imidazole buffer (300

mM Imidazole, 50 mM NaHepes, 1 M NaCl, 5 mM CaCl2, at pH = 7.5). All steps of protein purification from cell-free extracts were automated on a Tecan robot (Tecan, Switzerland), containing a

vacuum manifold. Homogeneity of purified proteins and molecular mass of recombinant enzymes were determined by SDS-PAGE in 14% (w/v) acrylamide gels and compared to a low molecular weight

(LMW) protein marker (18.5 to 96 KDa) (Nzytech, Portugal). The gel images were acquired with BioRad ChemiDoc XRS imaging system (Bio-Rad, Hercules, CA, USA). Protein concentration of enzyme

stock solutions varied between 0.13–26.7 g/L, as determined spectrophotometrically on NanoDrop 2000/2000c (NanoDrop Technologies; Thermo Fisher Scientific, Inc., Pittsburgh, PA, USA), and

the level of protein expression was determined accordingly (see Supplementary Table S1). PREPARATION OF MACROALGA CELL SUSPENSION The preparation of _L. digitata_ suspension at 20 g/L in PBS

solution, including a pre-wash step, centrifugation and algae re-suspension, was done using the procedure previously described for microalgae27. ENZYMATIC CELL WALL DISRUPTION The cell wall

disruption assay was performed in triplicate and with an enzyme concentration of 20 µg/ mL of incubation volume, as previously reported27, but with the following changes: the incubation of

the 24 well microplate (VWR Chemicals, West Chester, PA, USA) containing macroalgae suspension and alginate lyase was performed overnight at 160 rpm. Then, the microplate was centrifuged for

30 min at 3210 g and the supernatants and pellets were recovered. To precipitate and remove the enzymes, the supernatant for DNSA and HPLC analyses was boiled for 5 min, centrifuged for 5

min at 10,000 g and the supernatant recovered. REDUCING SUGARS MEASUREMENT To quantify the released reducing sugars, the 3,5-dinitrosalicylic acid (DNSA) method53 was used as previously

described for microalgae27, with the modification that 0.5 mL of glucose solutions or supernatants were mixed with 0.5 mL of DNSA reagent. FLUORESCENCE MICROSCOPIC OBSERVATIONS The pellets

from the enzyme cell wall disruption assay, were re-suspended in 0.5 mL of PBS solution for the initial screening or 1 mL of PBS for the assays with the most-active selected enzyme. The

suspension was mixed by pipetting to ensure that the algae pellets were suspended evenly. The re-suspended macroalgae biomass concentration was 40 mg/mL. The fluorochrome Calcofluor White

(Sigma-Aldrich, St. Louis, Mo, USA), that binds to the cell wall12,33,54, was added at 10 µL to the suspensions on adhesion slides (SuperFrost Plus Menzel Gläser, Thermo Scientific,

Braunschweig, Germany), followed by a solution of 10% KOH (VWR Chemicals, West Chester, PA, USA), in a proportion of 1:1:1. The fluorescence microscopic procedures were done as previously

reported27. Cells were observed with an epifluorescence microscope and images were captured with a Leica DFC-340FX (Leica, Wetzlar, Germany) camera system, in order to determine the

fluorescence intensity, expressed as arbitrary units, by using the Image J software (NIH, Bethesda, MA, USA). DETERMINATION OF CATALYTIC ACTIVITY OF ALGINATE LYASE The catalytic activity of

alginate lyase was analysed by two different methods: UV spectroscopy and determination of reducing sugars. The UV spectroscopy analysis followed the procedures described in a previous

report55, with some modifications. Briefly, a mixture of 1 mL of PBS solution containing 1% NaCl (pH = 7.5), 0.5 mL of alginic acid from brown algae (Sigma-Aldrich, Darmstadt, Germany) and 5

µl of alginate lyase (ID 22) at 4.37 mg/mL were mixed in a quartz cuvette. The alginate was previously dissolved in a PBS solution at a concentration of 0.3%. The increase in absorbance at

λmax 233 nm was continuously recorded during 1 h in an UV/Vis Spectrophotometer (Pharmacia LKB Ultrospec III spectrophotometer, Gemini, Apeldoorn, Netherlands), at 37 °C, to verify

linearity. The enzyme activity was maximum during 2 min. The maximum activity was reported in absorbance units (AU) defined as the increase in absorbance units per minute. The determination

of reducing sugars was done after stopping the enzyme reaction by using the DNSA reagent with subsequent heating of the samples, following the procedures previously described for the

measurement of reducing sugars27. THERMOSTABILITY AND PROTEOLYSIS EXPERIMENTS The alginate lyase was biochemically characterized, specifically for thermostability and proteolysis resistance.

The recombinant enzyme was purified through IMAC using gravity flow columns (His GraviTrap™, GE Healthcare, IL, USA), according to a previously described procedure29,30. The protein

concentration was adjusted at 0.83 g/L for both assays. The thermostability analysis was performed as previously reported27. The protein concentration in the recovered supernatant was

quantified in triplicate using a NanoDrop 2000/2000c (NanoDrop Technologies; Thermo Fisher Scientific, Inc., Pittsburgh, PA, USA), and the results were validated through visualization of 14%

SDS-PAGE gels, showing the intensity of the bands present in the supernatants. The gel images were acquired with BioRad ChemiDoc XRS imaging system (Bio-Rad, Hercules, CA, USA). The

proteolysis resistance analysis was performed as already described27. The alginate lyase was incubated with porcine pancreatin (VWR Chemicals, West Chester, PA, USA) or PBS solution and,

afterwards, the samples were analysed by 14% SDS-PAGE and compared to a low molecular weight (LMW) protein marker (18.5 to 96 KDa) (Nzytech, Portugal) (Fig. 5). The resultant images were

acquired with BioRad ChemiDoc XRS imaging system (Bio-Rad) and proteolysis was confirmed by visualizing fragments with different molecular weights. DETERMINATION OF MONO- AND

OLIGOSACCHARIDES The profile of mono- and oligosaccharides from the supernatants derived from incubation of _L. digitata_ with control and alginate assays was analysed and quantified by high

performance liquid chromatography (HPLC). For the analysis of monosaccharide profile, the chromatogram data was compared with individual monosaccharides standards composed by arabinose,

galactose, glucose, mannose plus xylose. Additional monosaccharides, including ribose, fructose, rhamnose, fucose, as well as its derivatives, such as galactosamine, glucosamine, sorbitol

and glucoronic acid were also used for comparison. For the analysis of oligosaccharide profile, the chromatogram data was compared with a mixture of cellulose-derived oligosaccharides. The

procedures followed a previously developed protocol27. The quantification of total oligosaccharides was based on a standard curve, using a range of concentrations from 0.025 to 0.60 mM of

glucose. The results were expressed as equivalent moles of released glucose _per_ 100 g of macroalga. DETERMINATION OF PROTEIN CONTENT After _L. digitata_ suspension and incubation with

control and alginate assays, the N content in lyophilised supernatant and residue fractions was quantified by the Kjeldahl method (984.13)56, assuming that no nitrogen from the media

interfere with the assay. The crude protein was calculated as N × 4.9257. PIGMENT ANALYSIS The content of chlorophyll _a_, chlorophyll _b_, total carotenoids and pheophytins were quantified

in supernatant and residue fractions from _L. digitata_ suspension, after control and alginate assays, as described by Hynstova et al.58, with slight modifications previously reported27,

except that total carotenoids also included the amount of fucoxanthins. The fucoxanthin content was quantified in the same way as the other pigments, but using the following formula

described in a recent study59: Cfuc = 6.39 × A445 − 5.18 × A663, where Cfuc is the concentration of fucoxanthin (mg/ml), A445 is the absorbance at λmax 445 nm and A663 is the absorbance at

λmax 663 nm. DETERMINATION OF FATTY ACID COMPOSITION Fatty acids from the lyophilised supernatants and pellets of _L. digitata_ after control and alginate assays were extracted as already

described for microalgae27. Fatty acids were esterified to methyl esters (FAME) by acidic catalysis based on the procedure described in a previous report4, but using 5 ml of

acetylchloride-methanol solution (1.25 M Sigma-Aldrich, St. Louis, Mo, USA) for up to 24.3 mg of sample. The analysis of FAME was done following procedures previously reported27, except for

the quantification of total FAME, that was carried out using nonadecanoic acid (19:0) as internal standard. Each fatty acid was expressed as a percentage of the sum of identified fatty acids

(% total fatty acids). The fatty acid present in a percentage inferior to 0.5% were included as others in Table 3. STATISTICAL ANALYSIS Data were analysed using the Generalised Linear Mixed

(GLM) model of the SAS software package (version 9.4; SAS Institute Inc., Cary, NC, USA), except data from the thermostability experiment, which were analysed using the MIXED procedure of

SAS. Normality was checked using Shapiro–Wilk test. All experiments were conducted in triplicate, except for the initial screening where experiments were conducted in duplicate. The error

bars on figures indicate the standard error of the mean (SEM). Results are presented as mean and SEM, and were considered significantly different when _p_ < 0.05. DATA AVAILABILITY All

data generated during this study are included in this published article. The datasets generated during the current study are available from the corresponding author on demand. REFERENCES *

Makkar, H. P. S. _et al._ Seaweeds for livestock diets: A review. _Anim. Feed Sci. Tech._ 212, 1–17. https://doi.org/10.1016/j.anifeedsci.2015.09.018 (2016). Article Google Scholar *

Holdt, S. L. & Kraan, S. Bioactive compounds in seaweed: functional food applications and legislation. _J. Appl. Phycol._ 23, 543–597. https://doi.org/10.1007/s10811-010-9632-5 (2011).

Article Google Scholar * Costa, M., Cardoso, C., Afonso, C., Bandarra, N. M. & Prates, J. A. M. Current knowledge and future perspectives of the use of seaweeds for livestock

production and meat quality: a systematic review. _J. Anim. Physiol. Anim. Nutr._ 00, 1–28. https://doi.org/10.1111/jpn.13509 (2021). Article Google Scholar * Cardoso, C. _et al._ Fatty

acid profiles of the main lipid classes of green seaweeds from fish pond aquaculture. _Food Sci. Nutr._ 5, 1186–1194. https://doi.org/10.1002/fsn3.511 (2017). Article Google Scholar *

Neto, R. T. _et al._ Screening of Ulva rigida, Gracilaria sp, Fucus vesiculosus and Saccharina latissima as functional ingredients. _Int. J. Mol. Sci._ https://doi.org/10.3390/Ijms19102987

(2018). Article Google Scholar * Campos, A. M. _et al._ Azorean macroalgae (_Petalonia binghamiae_, _Halopteris scoparia_ and _Osmundea pinnatifida_) bioprospection: a study of fatty acid

profiles and bioactivity. _Int. J. Food Sci. Technol._ 54, 880–890. https://doi.org/10.1111/ijfs.14010 (2019). Article Google Scholar * Givens, I. Animal nutrition and lipids in animal

products and their contribution to human intake and health. _Nutrients_ 1, 71–82. https://doi.org/10.3390/nu1010071 (2009). Article Google Scholar * FAO. World review in _The State of

World Fisheries and Aquaculture. Meeting the sustainable development goals_ (ed. FAO) 25, 74 (FAO, 2018). * Popper, Z. A. _et al._ Evolution and diversity of plant cell walls: from algae to

flowering plants. _Annu. Rev. Plant Biol._ 62, 567–590. https://doi.org/10.1146/annurev-arplant-042110-103809 (2011). Article Google Scholar * Michel, G., Tonon, T., Scornet, D., Cock, J.

M. & Kloareg, B. The cell wall polysaccharide metabolism of the brown alga Ectocarpus siliculosus Insights into the evolution of extracellular matrix polysaccharides in Eukaryotes. _New

Phytol._ 188, 82–97. https://doi.org/10.1111/j.1469-8137.2010.03374.x (2010). Article Google Scholar * Deniaud-Bouet, E. _et al._ Chemical and enzymatic fractionation of cell walls from

_Fucales_: insights into the structure of the extracellular matrix of brown algae. _Ann. Bot._ 114, 1203–1216. https://doi.org/10.1093/aob/mcu096 (2014). Article Google Scholar * Salmeán,

A. A. _et al._ Insoluble (1 -> 3), (1 -> 4)-β-D-glucan is a component of cell walls in brown algae (_Phaeophyceae_) and is masked by alginates in tissues. _Sci. Rep._ 7, 2880.

https://doi.org/10.1038/S41598-017-03081-5 (2017). Article Google Scholar * Deniaud-Bouet, E., Hardouin, K., Potin, P., Kloareg, B. & Herve, C. A review about brown algal cell walls

and fucose-containing sulfated polysaccharides: Cell wall context, biomedical properties and key research challenges. _Carbohydr. Polym._ 175, 395–408.

https://doi.org/10.1016/j.carbpol.2017.07.082 (2017). Article Google Scholar * Kadam, S. U., Tiwari, B. K. & O’Donnell, C. P. Extraction, structure and biofunctional activities of

laminarin from brown algae. _Int. J. Food Sci. Technol._ 50, 24–31. https://doi.org/10.1111/ijfs.12692 (2015). Article Google Scholar * Dobrincic, A. _et al._ Advanced technologies for the

extraction of marine brown algal polysaccharides. _Mar. Drugs_ https://doi.org/10.3390/Md18030168 (2020). Article Google Scholar * Øverland, M., Mydland, L. T. & Skrede, A. Marine

macroalgae as sources of protein and bioactive compounds in feed for monogastric animals. _J. Sci. Food Agr._ 99, 13–24. https://doi.org/10.1002/jsfa.9143 (2019). Article Google Scholar *

Adams, J. M., Gallagher, J. A. & Donnison, I. S. Fermentation study on _Saccharina latissima_ for bioethanol production considering variable pre-treatments. _J. Appl. Phycol._ 21,

569–574. https://doi.org/10.1007/s10811-008-9384-7 (2009). Article Google Scholar * Batista, S. _et al._ Use of technological processing of seaweed and microalgae as strategy to improve

their apparent digestibility coefficients in European seabass (Dicentrarchus labrax) juveniles. _J. Appl. Phycol._ 32, 3429–3446. https://doi.org/10.1007/s10811-020-02185-2 (2020). Article

Google Scholar * Fleurence, J., Massiani, L., Guyader, O. & Mabeau, S. Use of enzymatic cell-wall degradation for improvement of protein extraction from _Chondrus crispus_, _Gracilaria

verrucosa_ and _Palmaria palmata_. _J. Appl. Phycol._ 7, 393–397. https://doi.org/10.1007/Bf00003796 (1995). Article Google Scholar * Harnedy, P. A. & FitzGerald, R. J. Extraction of

protein from the macroalga _Palmaria palmata_. _Food Sci. Technol._ 51, 375–382. https://doi.org/10.1016/j.lwt.2012.09.023 (2013). Article Google Scholar * Joubert, Y. & Fleurence, J.

Simultaneous extraction of proteins and DNA by an enzymatic treatment of the cell wall of _Palmaria palmata_ (_Rhodophyta_). _J. Appl. Phycol._ 20, 55–61.

https://doi.org/10.1007/s10811-007-9180-9 (2008). Article Google Scholar * Mæhre, H. K., Jensen, I. J. & Eilertsen, K. E. Enzymatic pre-treatment increases the protein bioaccessibility

and extractability in Dulse (_Palmaria palmata_). _Mar. Drugs_ https://doi.org/10.3390/Md14110196 (2016). Article Google Scholar * Hou, X. R., Hansen, J. H. & Bjerre, A. B. Integrated

bioethanol and protein production from brown seaweed _Laminaria digitata_. _Bioresour. Technol._ 197, 310–317. https://doi.org/10.1016/j.biortech.2015.08.091 (2015). Article Google Scholar

* Ravanal, M. C. _et al._ The role of alginate lyases in the enzymatic saccharification of brown macroalgae, Macrocystis pyrifera and Saccharina latissima. _Algal Res._ 26, 287–293.

https://doi.org/10.1016/j.algal.2017.08.012 (2017). Article Google Scholar * Vanegas, C. H., Hernon, A. & Bartlett, J. Enzymatic and organic acid pretreatment of seaweed: effect on

reducing sugars production and on biogas inhibition. _Int. J. Ambient Energy_ 36, 2–7. https://doi.org/10.1080/01430750.2013.820143 (2015). Article Google Scholar * Habeebullah, S. F. K.

_et al._ Enzyme-assisted extraction of bioactive compounds from brown seaweeds and characterization. _J. Appl. Phycol._ 32, 615–629. https://doi.org/10.1007/s10811-019-01906-6 (2020).

Article Google Scholar * Coelho, D. _et al._ Novel combination of feed enzymes to improve the degradation of _Chlorella vulgaris_ recalcitrant cell wall. _Sci. Rep._ 9, 5382.

https://doi.org/10.1038/S41598-019-41775-0 (2019). Article Google Scholar * Coelho, D. _et al._ A two-enzyme constituted mixture to improve the degradation of _Arthrospira platensis_

microalga cell wall for monogastric diets. _J. Anim. Physiol. Anim. Nutr._ 104, 310–321. https://doi.org/10.1111/jpn.13239 (2020). Article Google Scholar * Costa, M. _et al._ Construction

of GH16 β-glucanase mini-cellulosomes to improve the nutritive value of barley-based diets for broilers. _J. Agr. Food Chem._ 62, 7496–7506. https://doi.org/10.1021/jf502157y (2014). Article

Google Scholar * Fernandes, V. O. _et al._ 1,3–1,4-β-glucanases and not 1,4-β-glucanases improve the nutritive value of barley-based diets for broilers. _Anim. Feed Sci. Technol._ 211,

153–163. https://doi.org/10.1016/j.anifeedsci.2015.11.007 (2016). Article Google Scholar * Ravindran, V. & Son, J. H. Feed enzyme technology: present status and future developments.

_Recent Pat. Food Nutr. Agric._ 3, 102–109. https://doi.org/10.2174/2212798411103020102 (2011). Article Google Scholar * Sichert, A. _et al._ Verrucomicrobia use hundreds of enzymes to

digest the algal polysaccharide fucoidan. _Nat. Microbiol._ 5, 1026–1039. https://doi.org/10.1038/s41564-020-0720-2 (2020). Article Google Scholar * Holzinger, A., Herburger, K., Kaplan,

F. & Lewis, L. A. Desiccation tolerance in the chlorophyte green alga _Ulva compressa_: does cell wall architecture contribute to ecological success?. _Planta_ 242, 477–492.

https://doi.org/10.1007/s00425-015-2292-6 (2015). Article Google Scholar * Zverlov, V., Volkov, I., Velikodvorskaya, T. & Schwarz, W. Highly thermostable endo-1,3-β-glucanase

(laminarinase) LamA from _Thermotoga neapolitana_: Nucleotide sequence of the gene and characterization of the recombinant gene product. _Microbiology_ 143, 1701–1708.

https://doi.org/10.1099/00221287-143-5-1701 (1997). Article Google Scholar * Kim, H. T. _et al._ Characterization of a recombinant endo-type alginate lyase (Alg7D) from _Saccharophagus

degradans_. _Biotechnol. Lett._ 34, 1087–1092. https://doi.org/10.1007/s10529-012-0876-9 (2012). Article Google Scholar * Rodríguez-Diaz, J., Carbajo, R., Pineda-Lucena, A., Monedero, V.

& Yebra, M. Synthesis of fucosyl-N-acetylglucosamine disaccharides by transfucosylation using α-L-fucosidases from _Lactobacillus casei_. _Appl. Environ Microbiol._ 79, 3847–3850.

https://doi.org/10.1128/AEM.00229-13 (2013). Article Google Scholar * Fontes, C. M. G. A., Hall, J., Hirst, B. H., Hazlewood, G. P. & Gilbert, H. J. The resistance of cellulases and

xylanases to proteolytic inactivation. _Appl. Microbiol. Biotechnol._ 43, 52–57. https://doi.org/10.1007/BF00170622 (1995). Article Google Scholar * Ekborg, N. A. _et al._ Saccharophagus

degradans gen. nov., sp. nov., a versatile marine degrader of complex polysaccharides. _Int. J. Syst. Evol. Microbiol._ 55, 1545–1549. https://doi.org/10.1099/ijs.0.63627-0 (2005). Article

Google Scholar * Mishima, Y. _et al._ A super-channel in bacteria: macromolecule uptake and depolymerization systems of Sphingomonas sp A1 with a special cell surface structure.

_Biotechnol. Genet. Eng. Rev._ 19, 105–119. https://doi.org/10.1080/02648725.2002.10648025 (2002). Article Google Scholar * Wang, D. M. _et al._ Optimal production of

4-deoxy-L-erythro-5-hexoseulose uronic acid from alginate for brown macro algae saccharification by combining endo- and exo-type alginate lyases. _Bioprocess. Biosyst. Eng._ 37, 2105–2111.

https://doi.org/10.1007/s00449-014-1188-3 (2014). Article Google Scholar * Manns, D., Deutschle, A. L., Saake, B. & Meyer, A. S. Methodology for quantitative determination of the

carbohydrate composition of brown seaweeds (_Laminariaceae_). _Rsc Adv._ 4, 25736–25746. https://doi.org/10.1039/c4ra03537b (2014). Article Google Scholar * Pilgaard, B. _et al._ Proteomic

enzyme analysis of the marine fungus _Paradendryphiella salina_ reveals alginate lyase as a minimal adaptation strategy for brown algae degradation. _Sci. Rep._

https://doi.org/10.1038/S41598-019-48823-9 (2019). Article Google Scholar * Loomis, W. D. & Battaile, J. Plant phenolic compounds and the isolation of plant enzymes. _Phytochemistry_

5, 423–438. https://doi.org/10.1016/S0031-9422(00)82157-3 (1966). Article Google Scholar * Jordan, P. & Vilter, H. Extraction of proteins from material rich in anionic mucilages:

Partition and fractionation of vanadate-dependent bromoperoxidases from the brown algae Laminaria digitata and L saccharina in aqueous polymer two-phase systems. _Biochim. Biophys. Acta_

1073, 98–106. https://doi.org/10.1016/0304-4165(91)90188-M (1991). Article Google Scholar * Fleurence, J. The enzymatic degradation of algal cell walls: a useful approach for improving

protein accessibility?. _J. Appl. Phycol._ 11, 313–314. https://doi.org/10.1023/A:1008183704389 (1999). Article Google Scholar * Osório, C. _et al._ Pigments content (chlorophylls,

fucoxanthin and phycobiliproteins) of different commercial dried algae. _Separations_ 7, 33. https://doi.org/10.3390/separations7020033 (2020). Article Google Scholar * Kanazawa, K. _et

al._ Commercial-scale preparation of biofunctional fucoxanthin from waste parts of brown sea algae _Laminaria japonica_. _Food Sci. Technol. Res._ 14, 573–582.

https://doi.org/10.3136/Fstr.14.573 (2008). Article Google Scholar * Lichtlé, C., Spilar, A. & Duval, J. Immunogold localization of light-harvesting and photosystem I complexes in the

thylakoids of _Fucus serratus_ (_Phaeophyceae_). _Protoplasma_ 166, 99–106 (1992). Article Google Scholar * Billakanti, J. M., Catchpole, O. J., Fenton, T. A., Mitchell, K. A. &

MacKenzie, A. D. Enzyme-assisted extraction of fucoxanthin and lipids containing polyunsaturated fatty acids from _Undaria pinnatifida_ using dimethyl ether and ethanol. _Process Biochem._

48, 1999–2008. https://doi.org/10.1016/j.procbio.2013.09.015 (2013). Article Google Scholar * Lee, M. R. F., Tweed, J. K. S., Cookson, A. & Sullivan, M. L. Immunogold labelling to

localize polyphenol oxidase (PPO) during wilting of red clover leaf tissue and the effect of removing cellular matrices on PPO protection of glycerol-based lipid in the rumen. _J. Sci. Food

Agric._ 90, 503–510. https://doi.org/10.1002/jsfa.3848 (2010). Article Google Scholar * Helbert, W. Marine polysaccharide sulfatases. _Front. Mar. Sci._

https://doi.org/10.3389/fmars.2017.00006 (2017). Article Google Scholar * Saez, N. J. & Vincentelli, R. High-throughput expression screening and purification of recombinant proteins in

_E. coli_. _Methods Mol. Biol._ 1091, 33–53. https://doi.org/10.1007/978-1-62703-691-7_3 (2014). Article Google Scholar * Miller, G. L. Use of dinitrosalicylic acid reagent for

determination of reducing sugar. _Anal. Chem._ 31, 426–428. https://doi.org/10.1021/Ac60147a030 (1959). Article Google Scholar * Schoenwaelder, M. E. A. & Clayton, M. N. The presence

of phenolic compounds in isolated cell walls of brown algae. _Phycologia_ 38, 161–166. https://doi.org/10.2216/i0031-8884-38-3-161.1 (1999). Article Google Scholar * Østgaard, K. Enzymatic

microassay for the determination and characterization of alginates. _Carbohydr. Polym._ 19, 51–59. https://doi.org/10.1016/0144-8617(92)90054-T (1992). Article Google Scholar * AOAC.

_Official methods of analysis_, 17th ed (Association of Official Analytical Chemists, 2000). * Lourenço, S. O., Barbarino, E., De-Paula, J. C., Pereira, L. O. D. S. & Marquez, U. M. L.

Amino acid composition, protein content and calculation of nitrogen-to-protein conversion factors for 19 tropical seaweeds. _Phycological Res._ 50, 233–241.

https://doi.org/10.1046/j.1440-1835.2002.00278.x (2002). Article Google Scholar * Hynstova, V. _et al._ Separation, identification and quantification of carotenoids and chlorophylls in

dietary supplements containing _Chlorella vulgaris_ and _Spirulina platensis_ using high performance thin layer chromatography. _J. Pharm. Biomed. Anal._ 148, 108–118.

https://doi.org/10.1016/j.jpba.2017.09.018 (2018). Article Google Scholar * Wang, L. J. _et al._ A rapid method for the determination of fucoxanthin in diatom. _Mar. Drugs_ 16, 33.

https://doi.org/10.3390/Md16010033 (2018). Article Google Scholar Download references ACKNOWLEDGMENTS This study was supported by Fundação para a Ciência e a Tecnologia (FCT, Lisbon,

Portugal; grant PTDC/CAL-ZOO/30238/2017), and CIISA (Project UIDB/00276/2020) and a PhD fellowship to DC (SFRH/BD/126198/2016). AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * CIISA - Centro

de Investigação Interdisciplinar Em Sanidade Animal, Faculdade de Medicina Veterinária, Universidade de Lisboa, 1300-477, Lisboa, Portugal Mónica Costa, Luís Pio, Pedro Bule, Cristina M.

Alfaia, Diogo Coelho, Carlos M. G. A. Fontes & José A. M. Prates * NZYTech - Genes and Enzymes, Estrada do Paço Do Lumiar, Campus do Lumiar, Edifício E, 1649-038, Lisboa, Portugal Vânia

Cardoso, Joana Brás, Carlos M. G. A. Fontes & José A. M. Prates Authors * Mónica Costa View author publications You can also search for this author inPubMed Google Scholar * Luís Pio

View author publications You can also search for this author inPubMed Google Scholar * Pedro Bule View author publications You can also search for this author inPubMed Google Scholar * Vânia

Cardoso View author publications You can also search for this author inPubMed Google Scholar * Cristina M. Alfaia View author publications You can also search for this author inPubMed

Google Scholar * Diogo Coelho View author publications You can also search for this author inPubMed Google Scholar * Joana Brás View author publications You can also search for this author

inPubMed Google Scholar * Carlos M. G. A. Fontes View author publications You can also search for this author inPubMed Google Scholar * José A. M. Prates View author publications You can

also search for this author inPubMed Google Scholar CONTRIBUTIONS M.C. prepared macroalgae biomass for the subsequent experiments. P.B. and C.M.G.A.F. constructed the databank with CAZYmes

and sulfatases. M.C. and P.B. generated recombinant plasmids. V.C. and J.B. were responsible for high-throughput production of recombinant enzymes. M.C. and L.P. preformed the incubations

and analysed reducing sugars and fluorescence intensity of algal cell walls, as well as pigment and protein contents. M.C. and C.M.A. analysed fat composition of macroalgae samples, and

C.M.A. analysed oligosaccharides amount. M.C. and D.C. performed statistics. D.C. assisted in the execution of the experiments. M.C. performed the manuscript preparation and literature

review. J.A.M.P. contributed to the overall research design, interpretation and discussion of the experimental results. All authors have revised, edited and approved the final manuscript.

CORRESPONDING AUTHOR Correspondence to José A. M. Prates. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. ADDITIONAL INFORMATION PUBLISHER'S NOTE

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION 1. SUPPLEMENTARY

INFORMATION 2. SUPPLEMENTARY INFORMATION 3. RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use,

sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative

Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated

otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or

exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. Reprints

and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Costa, M., Pio, L., Bule, P. _et al._ An individual alginate lyase is effective in the disruption of _Laminaria digitata_ recalcitrant

cell wall. _Sci Rep_ 11, 9706 (2021). https://doi.org/10.1038/s41598-021-89278-1 Download citation * Received: 06 January 2021 * Accepted: 16 April 2021 * Published: 06 May 2021 * DOI:

https://doi.org/10.1038/s41598-021-89278-1 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not

currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative