Revealing particle-scale powder spreading dynamics in powder-bed-based additive manufacturing process by high-speed x-ray imaging

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT Powder spreading is a key step in the powder-bed-based additive manufacturing process, which determines the quality of the powder bed and, consequently, affects the quality of the

manufactured part. However, powder spreading behavior under additive manufacturing condition is still not clear, largely because of the lack of particle-scale experimental study. Here, we

studied particle-scale powder dynamics during the powder spreading process by using _in-situ_ high-speed high-energy x-ray imaging. Evolution of the repose angle, slope surface speed, slope

surface roughness, and the dynamics of powder clusters at the powder front were revealed and quantified. Interactions of the individual metal powders, with boundaries (substrate and

container wall), were characterized, and coefficients of friction between the powders and boundaries were calculated. The effects of particle size on powder flow dynamics were revealed. The

particle-scale powder spreading dynamics, reported here, are important for a thorough understanding of powder spreading behavior in the powder-bed-based additive manufacturing process, and

are critical to the development and validation of models that can more accurately predict powder spreading behavior. SIMILAR CONTENT BEING VIEWED BY OTHERS SPATTERING MECHANISM OF LASER

POWDER BED FUSION ADDITIVE MANUFACTURING ON HETEROGENEOUS SURFACES Article Open access 27 November 2022 ADVANCEMENTS IN OPERANDO X-RAY TECHNIQUES FOR METAL ADDITIVE MANUFACTURING Article

Open access 29 November 2024 CHARACTERIZATION AND FLOWABILITY METHODS FOR METAL POWDERS Article Open access 03 December 2020 INTRODUCTION In the powder-bed-based additive manufacturing

process, powders are spread in a thin layer and then selectively melted/sintered by a heat source or selectively joined together by a liquid binding agent to form a part1,2,3. The quality of

the powder bed is known to be one of the main factors that influence the quality of the part being manufactured4. For example, in powder bed fusion process, it has been demonstrated that

improving the powder bed density and homogeneity decreases melting defects (such as denudation and porosity), and improves the final quality of the part5,6,7. Thus, it is important to study

and understand the spreading process in order to accurately predict powder bed quality8. Avalanche testing instruments and rheometers have been used to study powder flowability9,10,11,12.

However, the powder flow environment in avalanche testing instruments and rheometers is very different from the conditions in additive manufacturing. Since powder flow behavior strongly

depends on surrounding conditions, it is important to study and understand the flow behavior of powder under additive manufacturing conditions. Continuous models have been developed to

simulate and study the spreading process. Treating the powder as a continuous non-dense material that is subjected to shearing stresses, similar to the ones found during the spreading

process, provided an insight into the external forces that affect the powder. With this assumption, the influence of layer thickness, roller geometry, and initial powder properties on the

compacted powders’ relative density were studied13,14. However, as the powder was not a continuous material (but a collection of interacting individual elements) that interacted with the

environment as well, predictions of powder segregation and powder bed surface roughness require study at the particle scale. The discrete element method (DEM) has become the main tool to

computationally study the particle scale spreading process15. The influence of the spreading speed, coater type, and powder size distribution on the surface roughness and compaction of the

powder bed have been studied by DEM16,17,18,19,20. Recent simulation works have used experimentally measured powder size/shape distribution as input for simulation, which improves the

accuracy of the DEM model16,17,19,21. DEM results showed that defects (voids, surface roughness, thickness non-uniformity) in the powder bed can lead to defects (surface roughness and

porosity) in the final manufactured parts22,23. At the current state, the developed DEM models are based on many physical assumptions related to the mechanical properties that govern the

dynamic and mechanical behavior of the powder. Experimental characterization of the particle-scale dynamics of powder spreading process under additive manufacturing conditions is critical to

validating DEM models and uncovering powder spreading behavior in the powder-bed-based additive manufacturing process. However, this is very challenging for metals due to the lack of

transparency of metals to visible light and microscale interaction. Very recently, Chen _et al_. measured the dynamic repose angle during the powder spreading process by using a visible

light camera18. However, the dynamics of particle-scale powder spreading was not revealed, due to the limited resolution and penetration depth of conventional characterization tools. Very

recently, our team, as well as other research groups, have demonstrated that high-energy x-ray imaging could penetrate metals to study powder spattering, melting, and pore evolution during

metal additive manufacturing process24,25,26,27,28, indicating that x-ray imaging could be a powerful tool for studying powder spreading process. In this research, we developed an

experimental method based on high-speed high-energy x-ray imaging to characterize the powder spreading process with high spatial and temporal resolution and study the particle scale

spreading process _in-situ_. With this newly developed experimental approach, we revealed the evolution of the repose angle, the slope surface flow speed, and slope surface roughness during

the powder spreading process. We observed and analyzed the evolution and flow of two different types of powder clusters on the slope surface, and closely examined the particles that formed

such clusters. We analyzed the dynamic interaction of individual particles with their respective boundaries and calculated coefficients of friction between the powders and boundaries.

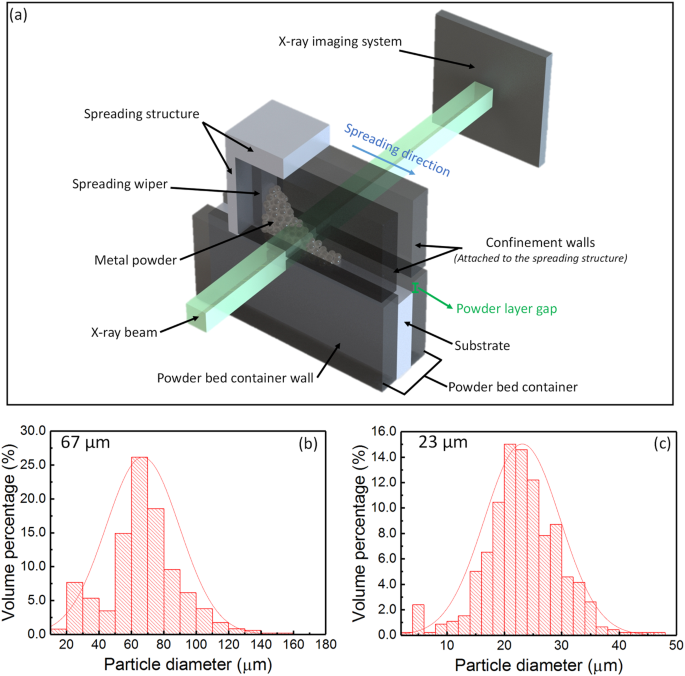

EXPERIMENTAL APPROACH High-speed high-resolution high-energy x-ray imaging was used to overcome the limitations of conventional characterization tools to study the particle-scale powder

spreading dynamics. A powder spreading system for _in-situ_ x-ray imaging experiments was developed to simulate the spreading process under additive manufacturing configurations, as shown in

Fig. 1a. The _in-situ_ experiment system consists of a powder spreading system and x-ray imaging system. The powder spreading system consists of a spreading structure (wiper and confinement

walls) and a powder bed container. The spreading wiper is an aluminum blade that is perpendicular to the powder bed substrate. Confinement walls, made of high-density graphite and attached

to each side of the aluminum blade, are designed to prevent the powders from flowing out of the spreading system. The powder bed container consists of container walls and a substrate. The

container walls are made of high density graphite and the substrate is aluminum. The substrate is controlled by a z-axis motion stage that creates a powder layer gap. The width and length of

the powder bed layer are 1 mm and 5 mm, respectively, while the layer thickness is set to be within a range of 80 µm to 160 µm. The low atomic number, low friction coefficient, and good

electrical conductivity of the high density graphite ensure that the spreading system has x-ray transparence, low friction, and an absence of accumulated static electric charge. Powders are

spread by an aluminum wiper (blade) at a spreading speed of 11.5 mm/s on an aluminum substrate. As the powder is spread, an x-ray beam passes through the powder bed, and the x-ray signal is

recorded by a detection system. The exposure time is 500 ns. A camera is set to record at a speed of 10,000 frames per second and an analysis of the images is done using the ImageJ29. The

metal powders used in our experiments are 316 L stainless steel powders of two different average diameters of 67 µm and 23 µm. Particle-size distributions of both powders are shown in Fig.

1b and c. The graphs of particle-size distribution were generated using images of the powders obtained through an optical microscope and then analyzed using ImageJ. RESULTS AND DISCUSSIONS

DYNAMIC REPOSE ANGLE, DYNAMIC SLOPE SURFACE ROUGHNESS AND SLOPE SURFACE FLOW SPEED The dynamic repose angle, dynamic slope surface roughness and slope surface flow speed are important

indicators of powder flow behavior during spreading. However, almost no experimental work has been reported on measuring these parameters during the spreading process under additive

manufacturing configurations with high temporal and spatial resolution. With our high-speed high-resolution x-ray imaging method (10,000 frames per second), we characterized, in detail, the

dynamic repose angle, the slope surface roughness and the slope surface flow speed of the powder front during the spreading process for 316 L stainless steel powders with two different

powder sizes (23 µm and 67 µm). Figure 2 shows the representative dynamic x-ray images acquired during spreading 316 L powders with average particle sizes of 67 µm and 23 µm. The repose

angle and surface roughness at each moment can be clearly observed, which allowed us to conduct a detailed analysis. The repose angle is indicated by yellow lines on each image. Figure 3

shows the evolution of the repose angle for the two powders over time. The repose angle for 67 µm powder fluctuates in a range of 34° and 37°, with an average value of 36° and standard

deviation of 2°. The repose angle for 23 µm of powder fluctuates in a range of 41° and 48°, with an average value of 45° and standard deviation of 4°. The dynamic repose angle data show that

the powders with smaller average particle size have a higher dynamic repose angle, larger fluctuation, and a higher standard deviation. Figure 4a,b show the representative x-ray images of

the slope surface of the powders with average diameters of 67 µm (a) and 23 µm (b). Figure 4c,d depict the representative slope surface profile for each powder. Figure 4e,f show the

evolution of the arithmetic average slope surface roughness (Ra) over time for the powders with average diameters of 67 µm (e) and 23 µm (f). A total of 35 measurements of “Ra” were obtained

for each powder, using a time lapse of 1.5 ms. The powder with an average diameter of 67 µm shows a larger average “Ra” of 38 µm with a standard deviation of 11 µm; the powder with an

average diameter of 23 µm shows a lower average “Ra” of 20 µm with a lower standard deviation of 6 µm. To evaluate the Ra value relative to the average particle diameter, the ratio of

Ra/average particle diameter was calculated. The calculated ratio of Ra/average diameter is 0.57 for the powder with an average diameter of 67 µm, which is smaller than the calculated ratio

of 0.87 for the powder with an average diameter of 23 µm. The lower ratio of Ra/average particle diameter in larger-sized powder may related to its better flowability. Figure 5 shows the

evolution of the slope surface speed over time for the two powders. A total of eight particles, flowing on the slope surface, were tracked. A time step of 0.5 ms was used between each

measurement. Figure 5a,c show the speed over time of the tracked particles for powders with average sizes of 67 µm and 23 µm. Figure 5b,d show the results of the calculated average slope

speed and variations in time for powders with average sizes of 67 µm and 23 µm. The 67 µm of powder showed an average slope surface speed of 77 mm/s that fluctuated within a range of 70 mm/s

and 84 mm/s, while the 23 µm of powder showed an average surface flow speed of 50 mm/s that fluctuated within a range of 36 mm/s and 64 mm/s. The reduced slope surface flow speed and higher

flowing variations shown by powder with a smaller average size, was consistent with the instabilities found in the dynamic repose angle. This confirmed the reduction in flowability and

increased flow irregularities as the average size of the powder was reduced. The large variation in the slope surface flow speed in the 23 µm powder might contribute to the larger ratio of

Ra/average particle diameter observed for this powder. DYNAMICS OF POWDER CLUSTERS A common instability during powder spreading in powder-bed-based additive manufacturing process is the

formation of powder agglomerations, also known as powder clusters. The clusters flow in a different way through the powder slope surface, when compared to individual particles. Therefore,

the study of their flowing behavior is important for characterizing the state of the powder that has flowed into the layer gap. Unfortunately, almost no experimental data has been reported

about the flowing behavior and evolution of powder clusters. It is also difficult for DEM simulations to accurately simulate the formation of powder clusters during the spreading process. By

using our high-speed high resolution x-ray imaging method, we conducted an _in-situ_ analysis of the behavior and evolution of two types of clusters flowing through the slope surface during

the spreading of 316 L stainless steel powder with an average size of 67 µm. Figure 6 shows representative images of the evolution of the tracked clusters as they flowed through the slope

surface. Figure 6(a–c) shows the evolution of the first cluster, designated as cluster “A”. Figure 6(d–f) shows the evolution of the second cluster, designated as cluster “B”. The high

quality of these images allow us to precisely track the position and morphologic changes of each cluster. The cluster structure and its translational and rotational directions are indicated

by the yellow, green, and red lines, respectively. It can be noticed that cluster “A” changes its structural configuration as it flows through the slope surface, in contrast with cluster “B”

which keeps a constant morphologic configuration. Therefore, cluster “A” was identified as a “soft cluster”, and cluster “B” as a “hard cluster”. The position of each cluster, as a function

of time, was tracked and their speed (over time) was computed and plotted. Figure 6g,h shows the speed over time for the tracked powder clusters “A” (soft cluster) and “B” (hard cluster)

respectively. A time lapse of 0.5 ms was used between each data point. The red dashed line indicates the linear fitting on each plot. Cluster “A” presented an average flow speed of 73 mm/s,

with a standard deviation of 23 mm/s, that fluctuated within a range of 50 mm/s and 96 mm/s, while cluster “B” presents an average flow speed of 67 mm/s, with a standard deviation of 15

mm/s, that fluctuated within a range of 52 mm/s and 82 mm/s. Compared to the data obtained for the slope surface flow speed of this powder, cluster “A” shows a 5 mm/s slower average flow

speed and had an increased standard deviation by 16 mm/s. Cluster “B” shows a 11 mm/s slower average flow speed and had an increased standard deviation of 8 mm/s. This data indicate the

instability that powder clusters added to the powder flow on the slope surface of the powder front. For a deeper understanding of the flow behavior of the powders within the powder clusters,

a particle scale analysis was conducted. Figure 7 shows representative images of the particle scale tracking for each of the powder clusters. Figure 7(a–c) show the evolution of the

particles found within cluster “A”. Figure 7(d–f) show the evolution of the particles found within cluster “B”. Particles larger than 60 µm and smaller than 40 µm are highlighted in each

image by red and yellow circles, respectively. The rotational direction of each particle is represented by the yellow arrows on each image. The position, as a function of time, of each

particle was tracked and the speed over time was computed and plotted. Figure 7g,h show the plotted speed over time of the tracked particles within each cluster. Figure 7g shows the speed

over time of the particles belonging to the soft cluster (cluster “A”), while Fig. 7h shows the speed over time for the particles within the hard cluster (cluster “B”). A total of six

particles were tracked, (PI, PII, PIII) within cluster “A”, and (PIV, PV, PVI) within cluster “B”. On a particle scale, Fig. 7g show substantially different relative speed variations for

particles PI, PII, and PIII belonging to cluster “A”. However, particles belonging to cluster “B” (PIV, PV, and PVI) showed relatively similar speed variations in Fig. 7h. The formation of a

soft cluster may result from van der Waals cohesion force and/or particle packing-induced jamming. A hard cluster may be a powder with satellites (formed in the atomization process) or may

form due to a much stronger van der Waals cohesion force, as compared to gravity force, because of the large difference in diameters. The irregular surfaces of these kinds of morphologies

restrict the free flow of powder during the spreading process. With this restricted flow, the powders tend to jam and create an irregular powder slope surface (shown in Fig. 7). With this

unstable flow, it might cause formation of cavities and voids in the powder bed. INTERACTION OF POWDERS WITH BOUNDARIES AND CALCULATION OF COEFFICIENTS OF FRICTION Metal powders interact

with the substrate and container walls during the powder spreading process. However, an analysis of these interactions using an experimental approach is challenging. As a consequence, almost

no experimental data has been reported on the analysis of the physical interactions between powder and the boundary surfaces at particle scale. Our high-speed x-ray imaging method allowed

us to analyze the dynamics of two individual particles as they flowed away from the powder front over two different surfaces. The first particle was found to flow over the aluminum

substrate, while the second particle flowed on the surface of the graphite container walls. Figure 8(a–c) illustrates representative dynamic x-ray images showing the motion of the two

particles. The previous and current position of each particle is indicated by the green and yellow circles, respectively. The particle flowing over the aluminum substrate was designated as

particle “A”, while the other one, flowing over the graphite container wall surface, was designated as particle “B”. The position of each particle, as a function of time, was tracked until

their movements had ceased due to friction. The speed over time was then computed, along with the average acceleration. Figure 8d,e show the speed versus time plots of the tracked particles

“A” and “B”. The red dashed line indicates the linear fitting on each plot. The corresponding linear fitting equations are also shown. The first derivative of each equation provides the

value of the current acceleration experienced by each particle. The computed acceleration for particle “A”, as it moved over the aluminum surface, was −2.5 m/s2, while the computed

acceleration for particle “B”, as it moved over the surface of the high-density graphite wall, was −1.8 m/s2. Using Newton’s second law of motion, the corresponding coefficients of friction

could be obtained. For the current translational movement, the force suffered by the particles is the friction force “Fc”. The kinetic friction coefficient could be obtained as: $${\mu

}_{c}=\frac{ma}{N}$$ (1) where “\({\mu }_{c}\)” is the kinetic coefficient of friction, “m” is the mass of the particle (\(2.1\,\times \,{10}^{-9}Kg\) for both particles), “a” is the

acceleration of the particles (−2.5 m/s2 and −1.8 m/s2 for particle A and B, respectively) and “N” is the normal force applied by the surface to the particle (\(2.1\,\times \,{10}^{-8}N\)

for both particles). The calculated kinetic friction coefficients are 0.25 for particle “A” moving over aluminum substrate, and 0.18 for particle “B” moving over high density graphite ground

surface. CONCLUSIONS Particle-scale powder spreading dynamics in powder-bed-based additive manufacturing process was revealed by high-speed high-energy x-ray imaging. The major conclusions

are summarized below. * (1) A high-speed high-resolution high-energy x-ray imaging approach was developed that enables the study of the particle-scale powder spreading dynamics in the

powder-bed-based additive manufacturing process. Evolution of the slope surface speed, slope surface roughness, and dynamics of powder clusters at the powder front are revealed and

quantified. * (2) The average powder size is an important parameter that affects powder flow dynamics during the spreading process. The powder with a larger average diameter of 67 µm showed

a higher average dynamic repose angle of 36°, and a higher average slope surface flow speed of 77 mm/s, as compared with the powder with a smaller average diameter of 23 µm, that showed an

average dynamic repose angle of 45°, and an average slope surface flow speed of 50 mm/s. * (3) Powder clusters affect powder spreading behavior. The powder clusters could not easily flow

through the slope surface. * (4) Interactions of powders with boundaries were characterized and the coefficients of friction were calculated. The calculated kinetic coefficients of friction

were 0.25 for particle moving over aluminum substrate, and 0.18 for particle moving over a high density graphite surface, which shows the potential for using the developed _in-situ_ x-ray

imaging approach to get critical boundary condition parameters for DEM modeling. The particle-scale powder spreading dynamics revealed are important for understanding powder spreading

behavior in the powder-bed-based additive manufacturing process. This is critical for the development and validation of more accurate models for predicting powder spreading behavior. METHODS

MATERIALS 316 L stainless steel powders of two different average diameters of 67 µm and 23 µm were used for this study. The 316 L stainless steel powders were produced using gas atomization

method. SUBSTRATE, SPREADING WIPER, CONTAINER WALLS AND CONFINEMENT WALLS The substrate, spreading wiper, container walls and confinement walls were machined from a 6061 aluminum block and

high density graphite block using a milling machine (Sherline 5810 NexGen). The surfaces were then polished by hand using an 800 (P-2400) silicon carbide metallurgical abrasive paper. Before

the experiments, the structures were cleaned using wipers and alcohol. X-RAY IMAGING SYSTEM The x-ray imaging system consists of an x-ray beam and detection system. The x-ray beam used is

an undulator-generated pink beam with the harmonic energy set to 25.7 keV and an energy bandwidth of 5~7% (Beamline 32-ID-B at the Advanced Photon Source). The x-ray detection system mainly

consists of a scintillator (LuAG:Ce, 100 µm thickness) and a high-speed camera (Photron FastCam SA-Z). POWDER SIZE DISTRIBUTION A total of 8 samples were extracted and analyzed for each 316

L stainless steel powder. Each sample was carefully spread over a glass substrate, then images were obtained using an optical microscope. “Analyze Particles” tool in ImageJ was used for the

computation of the particle diameter. A total of 2700 particles for each powder where analyzed. The powder size distribution graphs were then generated based on volumetric percentage. DATA

AVAILABILITY STATEMENT The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request. REFERENCES * Sames, W. J.,

List, F. A., Pannala, S., Dehoff, R. R. & Babu, S. S. The metallurgy and processing science of metal additive manufacturing. _Int. Mater. Rev._ 61, 315–360 (2016). Article Google

Scholar * Cima, M. & Cornie, J. Three-dimensional printing: rapid tooling and prototypes directly from a CAD model. _Int. Solid Free Form Fabr. Symp. Austin, TX_. 201–204 (1990). *

Kruth, J., Levy, G., Klocke, F. & Childs, T. H. C. Consolidation phenomena in laser and powder-bed based layered manufacturing. _CIRP Ann._ 56, 730–759 (2007). Article Google Scholar *

Gu, D. D., Meiners, W., Wissenbach, K. & Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. _Int. Mater. Rev._ 57, 133–164 (2012).

Article CAS Google Scholar * Gürtler, F. J. _et al_. Influence of powder distribution on process stability in laser beam melting: Analysis of melt pool dynamics by numerical simulations.

_Int. Solid Free Form Fabr. Symp. Austin, TX_. 1099–1117 (2014). * Lee, Y. S. & Zhang, W. Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive

manufacturing. _Int. Solid Free Form Fabr. Symp. Austin, TX_. 1154–1165 (2015). * Ziegelmeier, S. _et al_. An experimental study into the effects of bulk and flow behaviour of laser

sintering polymer powders on resulting part properties. _J. Mater. Process. Technol._ 215, 239–250 (2015). Article CAS Google Scholar * Zielinski, J., Vervoort, S., Mindt, H.-W. &

Megahed, M. Influence of powder bed characteristics on material quality in additive manufacturing. _BHM Berg- und Hüttenmännische Monatshefte_ 162, 192–198 (2017). Article Google Scholar *

Nalluri, V. R. & Kuentz, M. Flowability characterisation of drug-excipient blends using a novel powder avalanching method. _Eur. J. Pharm. Biopharm._ 74, 388–396 (2010). Article CAS

Google Scholar * Spierings, A. B., Voegtlin, M., Bauer, T. & Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. _Prog. Addit.

Manuf._ 1, 9–20 (2016). Article Google Scholar * Johanson, K. Effect of particle shape on unconfined yield strength. _Powder Technol._ 194, 246–251 (2009). Article CAS Google Scholar *

Nan, W., Ghadiri, M. & Wang, Y. Analysis of powder rheometry of FT4: Effect of particle shape. _Chem. Eng. Sci._ 173, 374–383 (2017). Article CAS Google Scholar * Shanjani, Y. &

Toyserkani, E. Material spreading and compaction in powder-based solid freeform fabrication methods: mathematical modeling. _Int. Solid Free. Fabr. Symp. Austin, TX_. 399–410 (2008). *

Johanson, J. R. A rolling theory for granular solids. _J. Appl. Mech._ 32, 842–848 (1965). Article ADS CAS Google Scholar * Herbold, E. B., Walton, O. & Homel, M. A. Simulation of

powder layer deposition in additive manufacturing processes using the discrete element method. _Technical Report, Lawrence Livermore National Laboratory_ (2015). * Parteli, E. J. R. &

Pöschel, T. Particle-based simulation of powder application in additive manufacturing. _Powder Technol._ 288, 96–102 (2016). Article CAS Google Scholar * Haeri, S., Wang, Y., Ghita, O.

& Sun, J. Discrete element simulation and experimental study of powder spreading process in additive manufacturing. _Powder Technol._ 306, 45–54 (2016). Article Google Scholar * Chen,

H., Wei, Q., Wen, S., Li, Z. & Shi, Y. Flow behavior of powder particles in layering process of selective laser melting: Numerical modeling and experimental verification based on

discrete element method. _Int. J. Mach. Tools Manuf._ 123, 146–159 (2017). Article Google Scholar * Haeri, S. Optimisation of blade type spreaders for powder bed preparation in additive

manufacturing using DEM simulations. _Powder Technol._ 321, 94–104 (2017). Article CAS Google Scholar * Zhang, W., Mehta, A., Desai, P. S. & Higgs, C. F. Machine learning enabled

powder spreading process map for metal additive manufacturing (AM). _Int. Solid Free Form Fabr. Symp. Austin, TX_. 1235–1249 (2017). * Nan, W. _et al_. Jamming during particle spreading in

additive manufacturing. _Powder Technol._ 338, 253–262 (2018). Article CAS Google Scholar * Mindt, H. W., Megahed, M., Lavery, N. P., Holmes, M. A. & Brown, S. G. R. Powder bed layer

characteristics: the overseen first-order process input. _Metall. Mater. Trans. A_ 47, 3811–3822 (2016). Article CAS Google Scholar * Mindt, H. W., Desmaison, O., Megahed, M., Peralta, A.

& Neumann, J. Modeling of powder bed manufacturing defects. _J. Mater. Eng. Perform._ 27, 32–43 (2018). Article CAS Google Scholar * Zhao, C. _et al_. Real-time monitoring of laser

powder bed fusion process using high-speed X-ray imaging and diffraction. _Sci. Rep._ 7, 3602 (2017). Article ADS Google Scholar * Guo, Q. _et al_. Transient dynamics of powder spattering

in laser powder bed fusion additive manufacturing process revealed by _in-situ_ high-speed high- energy x-ray imaging. _Acta Mater._ 151, 169–180 (2018). Article CAS Google Scholar *

Lun, C. _et al_. _In situ_ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. _Nat. Commun._ 9, 1–9 (2018). Article ADS Google Scholar * Calta, N. P. _et

al_. An instrument for _in situ_ time-resolved X-ray imaging and diffraction of laser powder bed fusion additive manufacturing processes. _Rev. Sci. Instrum_. 89, 55101 (2018). * Parab, N.

D. _et al_. Ultrafast X-ray imaging of laser – metal additive manufacturing processes research papers. _J. Synchrotron Radiat._ 25, 1467–1477 (2018). Article Google Scholar * Rasband, W.

I. J. _U. S. Natl. Institutes Heal. Bethesda, Maryland, USA_ //imagej.nih.gov/ij/ (2012). Download references ACKNOWLEDGEMENTS This work is funded by Honeywell Federal Manufacturing &

Technologies (FM&T), University of Missouri Research Board (UMRB), Intelligent Systems Center and Materials Research Center of Missouri S&T, National Science Foundation, and

Laboratory Directed Research and Development (LDRD) funding from Argonne National Laboratory, provided by the Director, Office of Science, of the U.S. Department of Energy under Contract No.

DE-AC02–06CH11357. The authors would like to thank Alex Deriy at the APS for his help on the beamline experiments. This research used resources of the Advanced Photon Source, a U.S.

Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02–06CH11357. All data prepared,

analyzed and presented has been developed in a specific context of this work and was prepared for internal evaluation and use pursuant to that work authorized under the referenced contract.

Reference herein to any specific commercial product, process or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement,

recommendation, or favoring by the United States Government, any agency thereof or Honeywell Federal Manufacturing & Technologies, LLC. This publication has been authored by Honeywell

Federal Manufacturing & Technologies under Contract No. DE-NA0002839 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article

for publication, acknowledges that the United States Government retains a nonexclusive, paid up, irrevocable, world-wide license to publish or reproduce the published form of this

manuscript, or allow others to do so, for the United States Government purposes. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Department of Mechanical and Aerospace Engineering, Missouri

University of Science and Technology, Rolla, MO, 65409, USA Luis I. Escano, Lianghua Xiong, Qilin Guo & Lianyi Chen * Department of Materials Science and Engineering, Missouri University

of Science and Technology, Rolla, MO, 65409, USA Luis I. Escano, Lianghua Xiong, Qilin Guo & Lianyi Chen * X-ray Science Division, Advanced Photon Source, Argonne National Laboratory,

Argonne, IL, 60439, USA Niranjan D. Parab, Cang Zhao, Kamel Fezzaa & Tao Sun * Department of Energy’s Kansas City National Security Campus Managed by Honeywell FM&T, Kansas City, MO,

64147, USA Wes Everhart Authors * Luis I. Escano View author publications You can also search for this author inPubMed Google Scholar * Niranjan D. Parab View author publications You can

also search for this author inPubMed Google Scholar * Lianghua Xiong View author publications You can also search for this author inPubMed Google Scholar * Qilin Guo View author publications

You can also search for this author inPubMed Google Scholar * Cang Zhao View author publications You can also search for this author inPubMed Google Scholar * Kamel Fezzaa View author

publications You can also search for this author inPubMed Google Scholar * Wes Everhart View author publications You can also search for this author inPubMed Google Scholar * Tao Sun View

author publications You can also search for this author inPubMed Google Scholar * Lianyi Chen View author publications You can also search for this author inPubMed Google Scholar

CONTRIBUTIONS L.C. conceived the project. L.I.E., N.D.P., L.X., Q.G., C.Z., K.F., W.E., T.S. and L.C. conducted the experiments, L.I.E. and L.C. analyzed the data. All authors discussed the

results. L.I.E. and L.C. wrote the manuscript. CORRESPONDING AUTHOR Correspondence to Lianyi Chen. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests.

ADDITIONAL INFORMATION PUBLISHER'S NOTE: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. RIGHTS AND PERMISSIONS

OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or

format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or

other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in

the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the

copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Escano, L.I., Parab, N.D.,

Xiong, L. _et al._ Revealing particle-scale powder spreading dynamics in powder-bed-based additive manufacturing process by high-speed x-ray imaging. _Sci Rep_ 8, 15079 (2018).

https://doi.org/10.1038/s41598-018-33376-0 Download citation * Received: 18 June 2018 * Accepted: 27 September 2018 * Published: 10 October 2018 * DOI:

https://doi.org/10.1038/s41598-018-33376-0 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not

currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative KEYWORDS * Powder Spreading * Additive Manufacturing Process *

Powder Clusters * Surface Roughness Slope * Repose Angle